The tooling can be easily changed and the relevant recipes for the selected attachment will be available to start testing immediately.

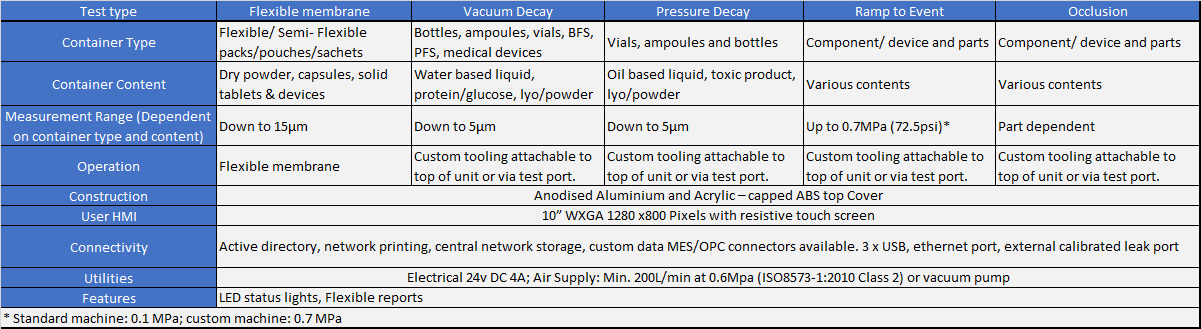

Testing methods that are compatible with the Multi-Q are:

Vacuum Decay, Utilizes the ASTM F2338-09 test method to test vials, ampoules, bottles, pre-filled syringes, blow filled seals, medical devices and trays. The non-destructive, deterministic leak test device can identify leaks and channel leaks as low as 5µm and gives a pass/fail result in 10 seconds.

Pressure Decay, Non-destructive, reliable and repeatable test method, ideal for testing the integrity of lyophilized and liquid filled vials, ampoules, bottles and other containers. The device shows a pass/fail result in 10 seconds and can identify leaks and channel leaks as low as 5µm.

Flexible Membrane, Non-destructive, tool-less leak detection device designed for flexible or semi-flexible packaging. Using hybrid membrane technology, the flexible head utilizes the ATM F2338-09 test method to perform the leak test. Ideal for testing gross or micron holes in pouches, sachets and bags that contain tablets, capsules, powders or devices.

Pressure Decay Bag Tester, Non-destructive leak test solution for empty bags including IV bags, blood bags and catheters. The deterministic, quantitative, and calibrated test method can identify gross as well as micron holes.

These non-destructive and deterministic test methods provide quick, reliable, and repeatable results enabling customers to improve the accuracy of their leak detection procedures and reduce cost as the method prevents the packaging from being damaged.

Other testing methods compatible with the Sepha Multi-Q include:

Ramp to Event, Destructive, deterministic, quantitative test method using pressure/vacuum to ramp to an event. Used for component testing to detect weak welds/seals etc.

Ramp to Proof Pressure, Non-destructive, deterministic, quantitative test method using pressure/vacuum to ramp to a target pressure.

Occlusion, Non-destructive, deterministic, quantitative test method using pressure drop/time. Typically used to test parts that must remain open to function correctly.